Profile

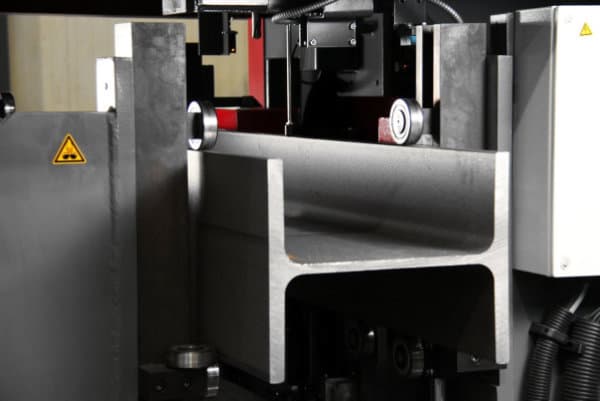

The Advantage-2 CNC beam drill line with its powerful material handling support, meticulous measurement capabilities and high speed designs are ideal for tandem installations with any of Voortman' automatic sawing systems.

Auto Standoff � This is not to be confused by vector standoff in 5-axis modes. Auto standoff works by using a changing surface. The angle of the Axis will determine how vertically it adjusts. With the buttons on your screen, you can make the vector-standoff change while the machine's running manually.